IoT_EoLT

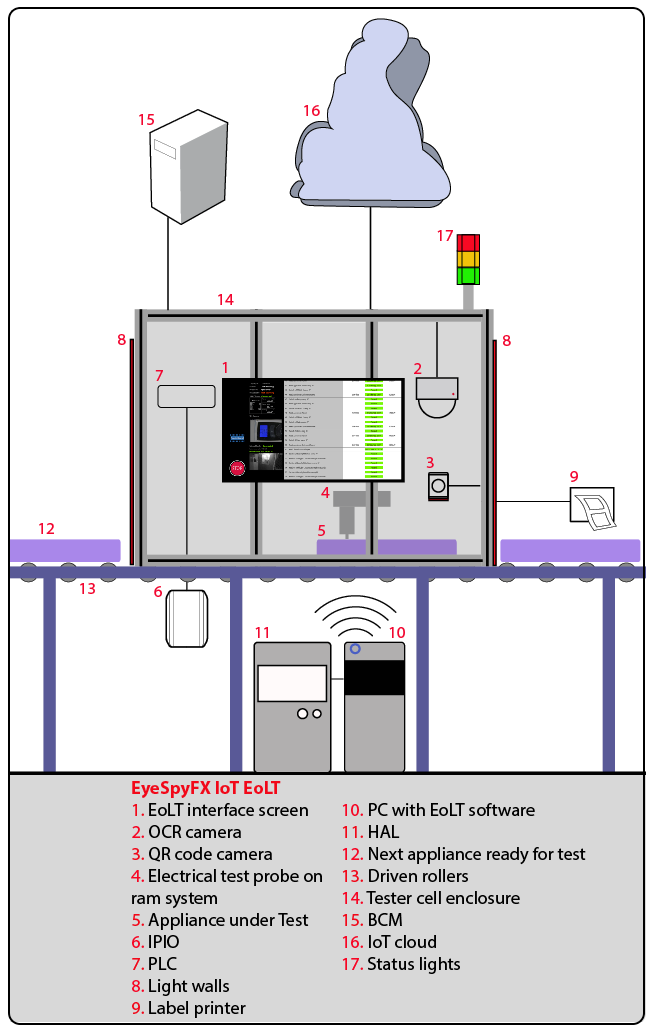

IoT End of Line Tester (IoT_EoLT)

IoT products differ from non-connected products because although they are mass produced each one is unique. To create that unique aspect every IoT product is christened.

As IoT products are manufactured and move toward the end the production a number of final checks and processes occur such as:

EyeSpyFX IoT End of Line Tester system carries out these processes.

EyeSpyFX IoT End of Line Testers are custom built to suit the specific production requirements for a specific environment and SKU. Testers vary in their physical manifestation from line to line.

Testers also vary in functional behaviour from line to line. Common operations include:

EyeSpyFX

Contact Us: info@eyespyfx.com

Office: (0044) 28 71867626 | Mobile: (0044) 7813780316